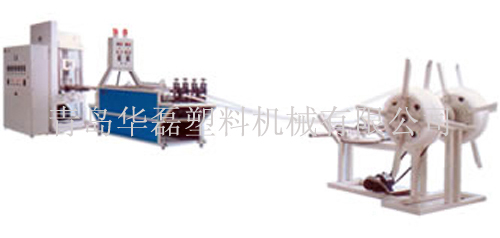

Peroxide cross-linking polythene pipe assembly line

|

|

Main machine |

|

7.5kw |

|

|

2x60w |

|

|

0.75kw |

|

|

9kw |

|

|

|

2x90w |

|

|

|

150w |

|

|

200L |

7.5kw |

|

100L |

5.5kw |

|

|

345L |

9kw |

|

150L |

6kw | |

| |

|

The RAM-200 peroxide cross-linking polythene pipe assembly line distinguishing feature:

The well-developed structure: The newly generation sphere crank mechanism of main machine adopts having high work efficiency.

The stable performance: The optimal overall structure design makes continuous and steady turning over a long period of time

The low noise: The noise is smaller than 45 db as two working positions simultaneous work.

The high yield: The single line annual yields over 100t

The steady pipe wall thick: Adopting the regulating mechanism of special technology, easy to regulate the thick of pipe wall, and having little fluctuate;

The online thermal character printing machine: writing distinct and endure wiping;

The assistance machines are integrated and dependable: automatic adjusting the pulling force, winding and discharging pipe.

Well-developed technology: Direct reaction and forming at 260 ?? high temperature, and not have to carry on the subsequence cross-linking process.

|

|

|